end wall flashing detail

Using the endwall flashing as a guide put it in place and use a pencil or a sharpie to mark the tops of the ribs of the panel where the flashing ends. Corner boards are prone to leakage due to shrinkage of materials and wind exposure.

Architectural Details Roofing Systems Standing Seam Roofing Standing Seam Roof Standing Seam Roofing

1 Piece Endwall Flashing - WS-28 Roof Pitch Required.

. The lower face of the Through the Wall Z Bar Flashing is extended past the end of the Vertical BlockingBacking Material an inch or two to cover the intersection of the Exterior Wall Covering and the end of the Vertical BlockingBacking Material. Step 1 Flashing 1 is a typical apron roof flashing. 10 Linear Feet Of Outside Foam Closures.

82 Build Supplement FlashingsSection 4 Roofwall intersections. Continuous wood blocking is first securely anchored to the top of the masonry and covered by a layer of building paper. CARRY FLASHING ½ MIN.

PREFABRICATED FLASHING END DAM. The End Wall Flashing provides protection where a roof intersects with a vertical wall. Start Your Project Sooner with Store Pickup.

Additional fixing may need to be considered in wind-exposed locations eg. The down direction harnesses the force of gravity and the out direction gets the water away from the building enclosure assemblies openings components and materials. Technical Specifications Brand Name.

10 Linear Feet Of Double Sided Butyl Tape. Meadows solutions are trusted by architects and contractors worldwide. This color matched flashing also provides a professional finishing touch to your roof.

Ad Treat Rough Openings with W. Gravity is the driving force behind drainage. 330 769-3546 Toll Free.

The cap flashing is set in the mortar joint between bricks. In general the sooner water is directed out the better. Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall.

Flashing is generally fixed to cladding or other flashing sections using rivets or self-drilling screws. For simple effective backup protection add a spline of asphalt felt paper at outside corners so that it extends 6 inches beyond the corner boards. SET IN MASTIC IF FLASHING IS NOT SELF-ADHERING.

The Type Of Screw Depends On The Material Of The Wall. Now you will know where to place the Z-trim. From any corner or end of wall.

Key Flashing Details at Building Wall Corners. How Doers Get More Done. On center and a minimum of 10 ft.

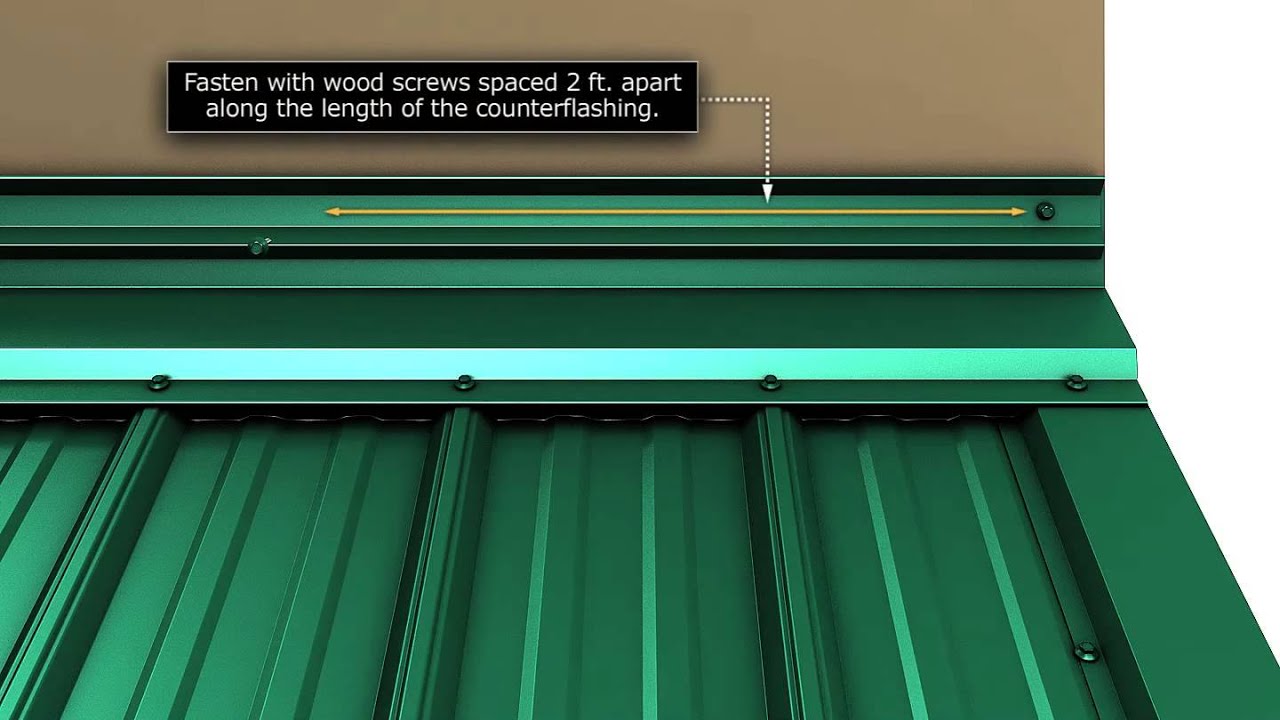

Fasteners close to folded edges generally cause the least distortion. Premium Pro-Steel Features 10 long. Find the Right Material For Every Job.

Family Company Since 1926. 10 Screws With Sealant Washer To Fasten Into The Wall. Used in conjunction with closure strips or butyl tape it reliably protects against water infiltration.

EXTEND FLASHING FLUSH OR BEYOND FACE OF MASONRY PREFABRICATED END DAM IN HEAD JOINT. The flashing upstand is carried up under the cladding and wall underlay and the ridge flashing roofing flashing junction ridge flashing barge flashing stop-end required to end of apron flashing. 07 65 00 - Flexible Flashing.

The lower edge is hemmed and laps the base flashing and is formed to be a snug fit against the base flashing. 07 63 00 - Sheet Metal Roofing Specialties. Endwall flashing is to be used where there is a lean-to type roof sloping away from the vertical wall.

Gibraltar End Wall Flashing can be used with most metal roofing profiles. 07 70 00 - Roof and Wall Specialties and Accessories. 07 71 13 - Manufactured Copings.

Joints are soldered or sealed see Figure 2. Flashing edges beneath cladding normally only require nominal attachment to battens. End dams are constructed by cutting and folding the flashing material.

A reglet trim may also be required. 07 71 23 - Manufactured Gutters and Downspouts. Plates and fasteners get installed at the seamvertically up the wall at 12 in.

10 Lap Screws Metal to Metal With Sealant Washer. The detail illustrates a copper cap flashing installed over a masonry wall. This detail shows the use of copper cap flashing extending over copper base flashing at the intersection of a shed roof with a masonry wall.

Its placed behind the wall steel and on top of the roof steel. Ad Shop Roofing Materials for Less. End dams should be constructed wherever flashings terminate within a wall to prevent water from simply flowing off the side of the flashing within the masonry wall rather than being directed to weeps where it can flow out of the wall.

BEYOND END OF LINTEL CAVITY INSULATION NOT. Ad Shop Roof Flashings Today Get Great Deals On Quality Products. 12 Tube Silicone Sealant.

Then youll need to mark where you are going to place the trim on the endwall. The cap flashing is then locked over the edge strips. 07 65 13 - Laminated Sheet Flashing.

10 Long Length 26 Gauge Metal Matches color of panel Use with OUTSIDE CLOSURES HOW MANY DO I NEED. ADD UP THE TOTAL LINEAR FEET OF ENDWALL NEEDED AND DIVIDE BY 95 Click the link below to see an installation guide for Endwall Flashing. Laps are heat-welded and the process continues until the wall flashing is complete.

END DAM PLACED PRIOR TO THROUGH-WALL FLASHING 2 RECOMMENDED. 07 71 00 - Roof Specialties. The maximum parapet wall height is not to exceed the width of a 10-ft.

Continuous copper edge strips are then fastened to the wood blocking. Hyload Headquarters 5020 Enterprise Parkway Seville Ohio 44273 Email. 07 65 19 - Plastic Sheet Flashing.

Mark the metal panels.

How To Install Polycarbonate Wall Google Search Hip Roof House Plans Hip Roof House Roof

Brick Wall Detail Google Search Drip Edge Masonry Rigid Insulation

Pitched Roof To Brick Wall Huse

Exposed Rafter Tails Roof Truss Design Roof Trusses Exposed Rafters

How To Install Endwall Trim For Union S Masterrib Panel Metal Roof Installation Roof Installation Roof Truss Design

Parapet Wall To Curtain Wall End Parapet Membrane Roof Curtain Wall

+A-1300_Page_19.jpg)